Health and Safety Executive Summarise Electrical Safety Guidance

The Health and Safety Executive (HSE) have issued a summary document containing their Electrical Safety Guidance. This important information is to help people to stay safe while working directly with electricity, and also to benefit those who might not work with sockets or power cords directly, but who perhaps work within building sites or in locations with a lot of electrical equipment. It is a comprehensive guide to maximising the chances of a safe working environment.

In order to stay safe when working around electricity, it is vital that all parties have a proper understanding of the hazards involved. Then, workers and management can begin to formulate a plan for the steps it is necessary to take in order to ensure the safety of staff, contractors, visitors and customers. Part of maintaining the proper level of safety around various electrical hazards is making sure that all of the electrical components which are in use are properly maintained, in order to avoid the many potential dangers and pitfalls of failing to follow the proper safety rules.

When ignored, electrical components present a number of hazards. A key one to bear in mind is the risk that an employee or contractor in a workplace could accidentally come into direct contact with live, exposed electrical parts. If that were to happen, both electric shocks and nasty burns could result, which could prove fatal. Furthermore, faulty installation and / or maintenance of electrical components could also result in fire, which in turn could lead to further injuries. Depending on the environment, and whether certain chemicals, dust or oxygen tanks are present in the area, there is also even a risk of explosion: all of this simply reinforces how seriously electrical safety has to be taken in any working environment.

A proper risk assessment must be undertaken, and should include an evaluation of what electrical equipment is being used in your workplace and, importantly, whether it was properly installed. It is possible to purchase specialist stationery for recording all safety checks, maintenance schedules and installation details, and this can help a workplace to be as safe as possible. Once that initial assessment has been performed, there are other things to take care of, for example you will want to make sure that all of that equipment continues to be properly maintained, and that all of the fuses and circuit breakers in use are the correct ones for the circuits which they protect. All cables, plugs, and fittings need to be regularly inspected as well.

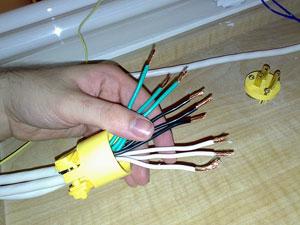

Some of the recommended inspection and maintenance procedures are surprisingly simple, leaving no business with an excuse to fail to carry them out. For example, components should be visually inspected to make sure that none of the plugs are damaged, that no internal wires are visible, and that no burn marks or stains or present. If any of these problems are spotted, or if the wires have been repaired with tape, the piece of equipment should be immediately repaired or replaced by a trained and competent person.

As well as looking in detail at careful installation and maintenance procedures, the HSE document also deals with issues surrounding overhead electric wires and underground cables. Many of the items in the HSE's electrical safety guidance document are common sense, or are procedures which will already be in place in many businesses. However, formalising them and ensuring that they are followed to the letter will contribute to an overall increase in safety for members of staff, visitors to your site and any contracted workers.

The HSE guidance in full can be found here.

About Peter Harrison

Pete has been involved in marketing for longer than her can remember